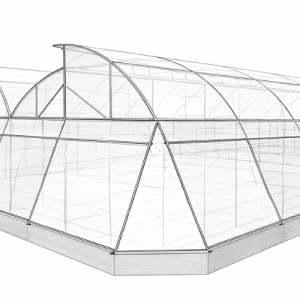

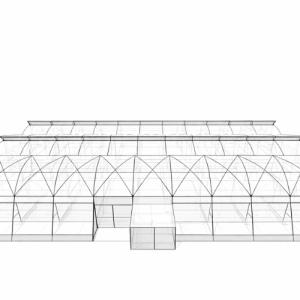

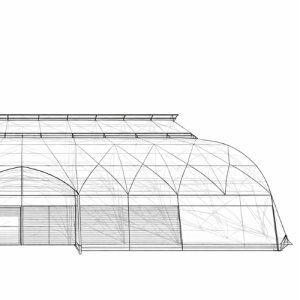

Inhydro delivers reliable and performance-driven hydroponics and polyhouse farming solutions designed to significantly enhance farm productivity and long-term profitability. We specialize in developing durable, high-quality structures that are engineered for Indian climatic conditions, ensuring stability, strength, and consistent performance throughout the year.

Customized Farming Solutions: Tailor-made polyhouse and hydroponic systems based on crop type, land size, and budget.

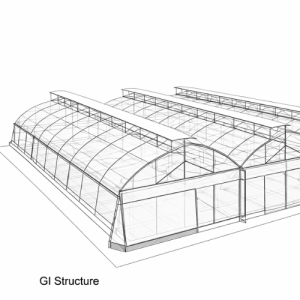

High-Quality Materials: Strong GI structures, UV-stabilized sheets, and durable components built for long-term use.

Improved Crop Yield & Quality: Optimized growing environment for better productivity and premium-grade produce.

Reviews

There are no reviews yet.