Inhydro Fan Pad Polyhouse – Advanced Climate Controlled Greenhouse System

BEST CROPS FOR fan pad polyhouse

| Crop Category | Best Crops for Fan Pad Polyhouse |

|---|---|

| High-Value Vegetables | Colored Capsicum (Red, Yellow), Dutch Cucumber, Cherry Tomato |

| Premium Fruits | Strawberry, Exotic Melons |

| Hydroponic Crops | Iceberg Lettuce, Romaine Lettuce, Kale |

| Floriculture Crops | Gerbera, Carnation, Dutch Rose |

| Export-Oriented Crops | Snack Cucumber, Zucchini, Baby Tomato |

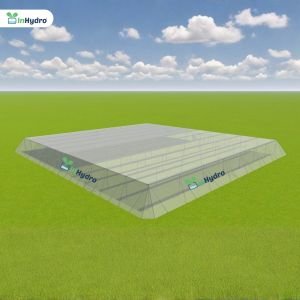

The Inhydro Fan & Pad Polyhouse is an advanced climate-controlled greenhouse system designed for high-value commercial cultivation. Built with a durable Hot-Dip Galvanized (HDG) steel structure, it ensures long-lasting performance and resistance to corrosion.

The system uses exhaust fans and cooling pads to regulate temperature and humidity, creating a stable microclimate for year-round crop production. Designed as per the guidelines of the National Horticulture Board (NHB) and Mission for Integrated Development of Horticulture (MIDH), it is eligible for government subsidy.

Rate -: 1440 Per/SQ.M

NHB TECHNICAL REQUIREMENTS – FAN & PAD POLYHOUSE

(As per NHB / MIDH Subsidy Guidelines – General Norms)

| Parameter | NHB Technical Requirement |

|---|---|

| Structure Type | Climate Controlled Fan & Pad Polyhouse |

| Structural Design | Gable Type / Arch Type (As per approved design) |

| Frame Material | Hot Dip Galvanized (HDG) Steel Pipes |

| Galvanization | Minimum 275 GSM Zinc Coating (or as per approved design) |

| Design Life | Minimum 15 Years |

| Foundation | RCC Foundation as per structural design |

| Welding | Not permitted on main members (only base plate if required) |

| Wind Load | As per local wind zone (IS 875 Standard) |

| Cladding Material | 200 Micron UV Stabilized Polyethylene Film |

| Insect Net | 40 Mesh UV Stabilized Insect Net |

| Cooling System | Evaporative Cooling Pads with Exhaust Fans |

| Pad Thickness | As per approved design (generally 100–150 mm) |

| Ventilation Type | Forced Ventilation (Fan & Pad System) |

| Bay Spacing | As per approved structural drawing |

| Gutter Height | As per approved design (generally 4–5 m) |

| Fastening System | Aluminum Profile with Spring Insertion |

| Drainage | Gutter & Rainwater Outlet System |

Project Gallery: NHB-Approved Shade Net House Installations

Standard sizes with indicative pricing as per government benchmark rates

The pricing mentioned below is based on the government approved benchmark rate for Dome Shape Shade Net House as prescribed under NHB and respective State Horticulture Department guidelines. The approved rate of ₹700 per square meter is applicable for protected cultivation structures constructed through empanelled agencies and includes the complete development of the shade net house.

| Size (Sq.M) | Approx. Area | Rate (₹/Sq.M) | Total Price (₹) | Subsidy (%) |

|---|---|---|---|---|

| 2000 Sq.M | ~0.5 Acre | ₹690 | ₹8,80,000 | Up to 50% |

| 4000 Sq.M | ~1 Acre | ₹690 | ₹17,60,000 | Up to 50% |

| 8000 Sq.M | ~2 Acres | ₹690 | ₹35,20,000 | Up to 50% |

Increase Your Farming Profit with Fan Pad Polyhouse

A Fan Pad Polyhouse is not just a protected structure — it is a fully climate-controlled commercial farming system designed to maximize yield, improve crop quality, and generate higher profits per square meter.

Unlike naturally ventilated systems, a fan and pad greenhouse actively controls temperature and airflow, allowing farmers to grow high-value crops even in extreme summer conditions. This level of control transforms traditional farming into a predictable and scalable agribusiness model.

Instead of depending on seasonal weather patterns, you get a controlled environment that ensures consistent production, stable quality, and premium market pricing.

How Fan Pad Polyhouse Increases Your Profit

1️⃣ Maximum Yield Per Square Meter

The fan and pad cooling system reduces inside temperature and maintains uniform airflow across the entire structure. This prevents heat stress and promotes uniform plant growth.

Because temperature and humidity remain within optimal range:

-

Plants grow faster

-

Flower drop reduces

-

Fruit size improves

-

Crop cycle shortens

Commercial growers often achieve significantly higher productivity compared to open-field or partially ventilated systems.

2️⃣ True Off-Season & Summer Production

In many parts of India, high temperatures during peak summer reduce crop performance. A climate controlled polyhouse allows you to:

-

Continue capsicum production in hot months

-

Grow premium cucumber varieties

-

Maintain cherry tomato quality year-round

-

Produce hydroponic leafy greens consistently

Off-season supply means higher market demand and premium pricing, directly increasing your net margin.

3️⃣ Premium Quality = Higher Market Value

Uniform temperature and airflow result in:

-

Better fruit color

-

Uniform size

-

Improved shelf life

-

Reduced cracking & sunburn

This makes your produce suitable for:

-

Modern retail chains

-

Export markets

-

Contract farming buyers

-

Hotels & institutional supply

Higher grade produce always commands better pricing.

4️⃣ Climate Stability Reduces Crop Failure Risk

Open-field farming exposes crops to:

-

Heat waves

-

Heavy rainfall

-

Sudden storms

-

Pest pressure

Fan Pad Polyhouse creates a controlled microclimate that reduces environmental stress. This lowers crop loss risk and improves production predictability.

For commercial investors, reduced risk means stable returns.

5️⃣ Optimized Water & Nutrient Management

Fan pad systems work efficiently with:

-

Drip irrigation

-

Fertigation systems

-

Hydroponic setups

Because the environment is controlled:

-

Water evaporation reduces

-

Nutrient uptake improves

-

Wastage decreases

Lower input cost combined with higher output directly improves profit per cycle.

6️⃣ Ideal for High-Value Commercial Crops

Fan Pad Polyhouse is most profitable for:

-

Colored Capsicum (Red & Yellow)

-

Dutch Cucumber

-

Cherry Tomato

-

Strawberry

-

Gerbera & Floriculture

-

Hydroponic Leafy Greens

These crops require stable climate conditions that only a fully controlled greenhouse can provide.

7️⃣ Better Return on Investment (ROI)

Although the initial investment in a fan pad greenhouse is higher than a naturally ventilated system, the earning potential is also significantly greater because:

-

Yield per square meter increases

-

Off-season production boosts pricing

-

Export-grade quality improves margins

-

Production cycles remain consistent

For serious commercial growers, Fan Pad Polyhouse offers a long-term scalable income model.

| Weight | 15 kg |

|---|---|

| Panel Material | High-quality UV-stabilized Polypropylene (PP) |

| Panel Size | 396 mm (L) × 150 mm (H) × 116 mm (D) |

| Pot Size | 122 mm × 80 mm × 80 mm |

| Plant Capacity | 3 plants per panel |

| Plant Density | 5 plants per sq. ft. |

| Configuration | Modular, expandable, wall-mounted or free-standing |

| Watering System | Integrated drip irrigation with nutrient recirculation |

| Vertical Wall Garden | 18 Planter, 27 Planter, 36 Planter |

Add a review Cancel reply

Additional Technical Specifications & Government Compliance Standards

The Inhydro NVPH Polyhouse (Naturally Ventilated Polyhouse) is designed and manufactured in strict accordance with the technical guidelines prescribed by the National Horticulture Board (NHB) and the Mission for Integrated Development of Horticulture (MIDH). Every structural component, including the Hot-Dip Galvanized (HDG) steel framework, ventilation system, and UV-stabilized covering material, is engineered to meet government-approved specifications. This ensures high structural reliability, long service life, optimal crop protection, and eligibility for subsidy schemes under approved horticulture programs. Designed specifically for Indian agro-climatic conditions, the Inhydro NVPH Polyhouse delivers durability, performance, and compliance with national protected cultivation standards.

Key Compliance Points:

HDG (Hot-Dip Galvanized) steel structure with prescribed micron coating thickness

Wind load and structural design as per government-approved standards

UV-stabilized polyethylene film as per NHB specifications

Proper roof and side ventilation system for natural airflow

Foundation and column spacing as per subsidy norms

1️⃣ STRUCTURAL PIPE SPECIFICATIONS (CRITICAL FOR SUBSIDY)

| Structural Member | Pipe OD | Thickness | Material | Remarks |

|---|---|---|---|---|

| Main Columns | 60 mm | 2.0 – 2.5 mm | HDG Stee | Primary load bearing, wind resistant structure |

| Foundation Insert Pipe | 60 mm | 2.5 mm | HDG Steel | Embedded in RCC footing (1–1.5 m depth typical) |

| Roof Arches | 48 mm | 2.0 mm | HDG Steel | Supports polyfilm covering |

| Ridge Pipe | 42 mm | 2.0 mm | HDG Steel | Top structural alignment & stability |

| Roof Purlins | 42 / 48 mm | 2.0 mm | HDG Steel | Polyfilm & shade net support |

| Side Purlins | 42 mm | 2.0 mm | HDG Steel | Lateral reinforcement |

| Cross & Wind Bracing | 33 mm | 2.0 mm | HDG Steel | Wind load resistance (120–150 km/h zone dependent) |

| Curtain Runner Pipe | 42 mm | 2.0 mm | HDG Steel | Manual/automatic roll-up ventilation system |

2️⃣ Pipe & Coating Standards

| Parameter | Standard |

|---|---|

| Pipe Type | Circular Hot Dip Galvanized Steel Pipes (IS 1161 / IS 4923) |

| Galvanization | Hot Dip Galvanized as per IS 4759:2019 |

| Zinc Coating | Minimum 275 GSM |

| Jointing Method | Nut–Bolt & Clamp System (GI Hardware) |

| Welding | Not permitted in main structural members (except base plate) |

3️⃣ Cladding & Cooling Specifications

| Parameter | Specification |

|---|---|

| Cladding Material | 200 Micron UV Stabilized Polyethylene Film |

| Insect Net | 40 Mesh UV Stabilized Insect Net |

| Cooling Pads | Cellulose Evaporative Cooling Pads (100–150 mm Thickness) |

| Exhaust Fans | Heavy Duty Exhaust Fans (Capacity as per design requirement) |

| UV Life | 3–5 Years (Film), as per manufacturer specification |

4️⃣ Foundation & Civil Works

| Item | Specification |

|---|---|

| Foundation Type | RCC Footing with Reinforcement |

| Concrete Grade | M20 or higher |

| Depth | 900 mm (or as per structural design & wind zone) |

| Purpose | Wind Load & Climate-Controlled Structural Stability |

5️⃣ Scope of Supply & Installation

| Item | Status |

|---|---|

| Structure & erection | ✅ Included with complete fabrication |

| Poly Film & Insect Net fixing | ✅ Included with UV stabilized material |

| Fan & Cooling Pad System | ✅ Included with installation & testing |

| Civil foundation work | ✅ Included with RCC footing |

| Inspection & subsidy readiness | ✅ Included with documentation support |

6️⃣ Exclusions

| Item | Status |

|---|---|

| Planting material | ❌ Not Included in project cost |

| Fertilizers & pesticides | ❌ Not Included in project cost |

| Electricity connection & panel approval | ❌ Not Included in project cost |

The cost of a Fan & Pad Polyhouse in India typically ranges between ₹60 lakh to ₹90 lakh per acre (approx. 4,047 sq.m) depending on structural specifications, automation level, cooling system capacity, and region. Basic semi-automatic systems fall on the lower range, while fully automated climate-controlled systems with sensors and controllers increase the overall project cost.

Fan & Pad Polyhouses constructed as per the guidelines of the National Horticulture Board (NHB) and Mission for Integrated Development of Horticulture (MIDH) are eligible for government subsidy. Subsidy generally 50% depending on the state, farmer category (general/SC/ST/women), and project size. Final approval is subject to inspection and compliance with technical norms.

Electricity consumption depends on the number of exhaust fans, water pumps, and automation systems installed. For a 1-acre Fan & Pad Polyhouse, monthly electricity expenses can range between ₹40,000 to ₹80,000 depending on climate conditions and usage duration. Regions with extreme summer temperatures may require longer cooling hours.

Yes, Fan & Pad Polyhouses are especially suitable for hot and dry regions because the cooling pad system effectively reduces internal temperature. Farmers cultivating colored capsicum, cucumber, cherry tomato, and exotic vegetables often achieve higher yields and premium market prices due to controlled climate conditions and year-round production.

NVPH (Naturally Ventilated Polyhouse) has lower initial investment and minimal electricity dependency. Fan & Pad Polyhouse requires higher capital investment and operational cost but offers better climate control, uniform crop quality, and export-grade production potential. For commercial large-scale farming and export-oriented cultivation, Fan & Pad systems generally provide better long-term returns.

The number of exhaust fans depends on greenhouse length, airflow design, and cooling capacity requirements. Typically, multiple high-capacity exhaust fans are installed to maintain uniform airflow across the structure. Proper fan spacing and CFM (Cubic Feet per Minute) calculations are essential to maintain optimal internal temperature.

High-value crops such as colored capsicum, Dutch cucumber, cherry tomato, lettuce, gerbera, and roses generally provide higher returns under controlled polyhouse conditions. Crop profitability depends on market demand, quality standards, and proper crop management practices.

For commercial viability, at least 1,000 sq.m to 4,000 sq.m is recommended. However, many farmers prefer starting with 1 acre (approx. 4,047 sq.m) for better economies of scale. Proper land leveling, drainage, and water availability are essential before installation.

The payback period typically ranges between 2 to 4 years, depending on crop selection, market demand, operational efficiency, and subsidy benefits. High-value crops like colored capsicum and cucumber can significantly reduce the recovery period if managed properly.

Good-quality water with low salinity (EC within recommended limits) is essential for both irrigation and cooling pad operation. Poor water quality can reduce crop yield and damage cooling pads over time. Regular water testing is strongly recommended.

Yes, but proper ventilation design and airflow calculation are critical. In high-humidity areas, humidity management becomes more important than temperature control. Correct fan capacity and pad thickness help maintain balanced internal conditions.

Modern Fan & Pad Polyhouses may include:

Temperature and humidity sensors

Climate control panels

Drip irrigation automation

Fertigation systems

Timer-based or sensor-based cooling systems

Automation improves crop uniformity and reduces manual monitoring effort.

Annual maintenance costs include electricity charges, cooling pad replacement (every 3–4 years), minor structural inspections, and film replacement (every 3–5 years). Proper maintenance ensures long-term durability and consistent crop performance.

Contact Us For More Information Regarding our Hydroponic projects with our team which consists of experts and well-trained professionals to provide services of the highest quality.

Reviews

There are no reviews yet.